Tesla Mechanical Designs Help Mastering Machine Design for Optimal Performance

Mastering machine design by avoiding critical mistakes—ensuring durability, ease of maintenance, safety, and long-term performance.

Machine design excellence is rooted in anticipation and detail. We transform challenges into reliable, lasting solutions by building dependability into every detail, from concept to prototype.”

NY, UNITED STATES, July 28, 2025 /EINPresswire.com/ -- Machine design is both an art and a science. Even the most experienced engineers can fall prey to critical mistakes that compromise reliability, efficiency, or user satisfaction. Tesla Mechanical Designs stands at the forefront of mechanical innovation, leveraging years of expertise to help clients sidestep the most common pitfalls in machine design. Through a meticulous and proactive methodology, Tesla Mechanical Designs mitigates five common yet critical mistakes that often plague machine development, ensuring optimal performance, longevity, and cost-effectiveness for clients.— Prex Poojara, Director, Tesla Mechanical Designs

"At Tesla Mechanical Designs, we believe that true innovation lies in foresight and meticulous planning," says Kuldeep Gajjar, Director at Tesla Mechanical Designs. "Our expertise in machine design is a testament to our decades of experience in the field, distilling complex engineering challenges into actionable strategies. We have witnessed firsthand the pitfalls of inadequate design, and our aim with every project we undertake is to equip our clients with machines that are not just functional, but exceptional – built to perform flawlessly under real-world conditions, be easy to maintain, cost-effective in the long run, and inherently safe. This isn't just about avoiding mistakes; it is about setting new benchmarks for mechanical design and empowering our clients to achieve optimal performance."

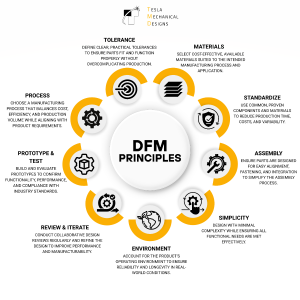

Tesla Mechanical Designs delves deep into five pivotal areas where design vulnerabilities most frequently occur, offering a clear roadmap to avoiding these pitfalls through its proven methodologies.

𝟏. 𝐃𝐞𝐬𝐢𝐠𝐧𝐢𝐧𝐠 𝐟𝐨𝐫 𝐑𝐞𝐚𝐥-𝐖𝐨𝐫𝐥𝐝 𝐂𝐨𝐧𝐝𝐢𝐭𝐢𝐨𝐧𝐬: 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠 𝐟𝐨𝐫 𝐋𝐨𝐧𝐠𝐞𝐯𝐢𝐭𝐲

𝐓𝐡𝐞 𝐏𝐫𝐨𝐛𝐥𝐞𝐦: 𝐈𝐠𝐧𝐨𝐫𝐢𝐧𝐠 𝐄𝐧𝐯𝐢𝐫𝐨𝐧𝐦𝐞𝐧𝐭𝐚𝐥 𝐅𝐚𝐜𝐭𝐨𝐫𝐬

Machines rarely operate in ideal laboratory conditions. Environmental factors such as heat, vibration, humidity, and corrosion can drastically shorten the lifespan of mechanical systems if not properly accounted for. Many designers overlook these real-world challenges, leading to premature failures and costly downtime.

𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬’ 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧

Tesla Mechanical Designs embeds environmental considerations into every phase of the design process:

• Comprehensive Requirement Analysis: Each project begins with a meticulous examination of operational environments, including temperature extremes, humidity, vibration levels, and exposure to corrosive agents.

• Advanced Simulation Tools: The use of Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) allows engineers to predict how designs will perform under real-world stresses, identifying potential weak points before they become failures.

• Material and Coating Selection: By selecting materials and protective coatings tailored to the environment, Tesla Mechanical Designs ensures machines resist corrosion, thermal expansion, and vibration-induced fatigue.

• Field Testing: Prototypes are tested in simulated or actual field conditions to validate performance and longevity.

This holistic approach results in machines that not only meet but exceed expectations for durability and reliability.

𝟐. 𝐁𝐮𝐢𝐥𝐭 𝐟𝐨𝐫 𝐄𝐚𝐬𝐞 𝐨𝐟 𝐔𝐬𝐞 & 𝐌𝐚𝐢𝐧𝐭𝐞𝐧𝐚𝐧𝐜𝐞: 𝐃𝐞𝐬𝐢𝐠𝐧𝐢𝐧𝐠 𝐟𝐨𝐫 𝐎𝐩𝐞𝐫𝐚𝐭𝐢𝐨𝐧𝐚𝐥 𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐜𝐲

𝐓𝐡𝐞 𝐏𝐫𝐨𝐛𝐥𝐞𝐦: 𝐎𝐯𝐞𝐫𝐥𝐨𝐨𝐤𝐢𝐧𝐠 𝐌𝐚𝐢𝐧𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲

A machine, no matter how technologically advanced, falls short if it is difficult to operate or cumbersome to maintain. Neglecting user experience and maintenance accessibility during the design phase is a critical error that can lead to increased operational costs, decreased productivity, and heightened safety risks. Downtime for repairs or routine servicing can be a major financial drain, and complex maintenance procedures can deter proper upkeep, shortening a machine's lifespan.

𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬’ 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧

Tesla Mechanical Designs prioritizes maintainability and user experience:

• Design for Disassembly: Components are arranged for easy access, with modular sub-assemblies and quick-release fasteners that minimize the time and tools required for maintenance.

• Wear Part Planning: High-wear components are designed to be easily replaceable, reducing the need for extensive disassembly or specialized tools.

• Clear Documentation: Every design is accompanied by detailed maintenance guides, exploded diagrams, and troubleshooting instructions, empowering operators to perform routine servicing efficiently.

• User-Centric Feedback Loops: Input from end-users and maintenance teams is integrated early in the design process, ensuring that the final product aligns with real-world needs.

By making maintainability a core design principle, Tesla Mechanical Designs delivers machines that maximize uptime and minimize lifecycle costs.

𝟑. 𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐒𝐞𝐥𝐞𝐜𝐭𝐢𝐨𝐧 𝐟𝐨𝐫 𝐃𝐮𝐫𝐚𝐛𝐢𝐥𝐢𝐭𝐲 & 𝐂𝐨𝐬𝐭-𝐄𝐟𝐟𝐞𝐜𝐭𝐢𝐯𝐞𝐧𝐞𝐬𝐬

𝐓𝐡𝐞 𝐏𝐫𝐨𝐛𝐥𝐞𝐦: 𝐈𝐧𝐚𝐩𝐩𝐫𝐨𝐩𝐫𝐢𝐚𝐭𝐞 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐂𝐡𝐨𝐢𝐜𝐞𝐬

Selecting the wrong material can lead to early failure, excessive wear, or inflated costs. Many designers fail to consider the full range of operational stresses, leading to machines that are either over-engineered (or expensive) or under-engineered (and fragile).

𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬’ 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧

Tesla Mechanical Designs employs a rigorous material selection process:

• Application-Centric Analysis: Engineers consider all operational factors—temperature, humidity, pressure, load, and stress—when choosing materials.

• Material Property Research: Detailed analysis of datasheets for strength, fatigue life, corrosion resistance, and thermal properties ensures optimal performance.

• Testing and Validation: Materials are validated through simulation and real-world testing, confirming that they meet the demands of the application.

• Cost-Benefit Optimization: The team balances durability with cost-effectiveness, selecting materials that provide the best value without compromising safety or longevity.

This disciplined approach ensures machines are robust, reliable, and competitively priced.

𝟒. 𝐄𝐧𝐬𝐮𝐫𝐢𝐧𝐠 𝐔𝐧𝐜𝐨𝐦𝐩𝐫𝐨𝐦𝐢𝐬𝐞𝐝 𝐒𝐚𝐟𝐞𝐭𝐲 & 𝐂𝐨𝐦𝐩𝐥𝐢𝐚𝐧𝐜𝐞

𝐓𝐡𝐞 𝐏𝐫𝐨𝐛𝐥𝐞𝐦: 𝐍𝐞𝐠𝐥𝐞𝐜𝐭𝐢𝐧𝐠 𝐒𝐚𝐟𝐞𝐭𝐲 𝐒𝐭𝐚𝐧𝐝𝐚𝐫𝐝𝐬

A powerful machine is of little value if it endangers users or fails to meet regulatory requirements. Overlooking safety can result in accidents, legal liabilities, and reputational damage.

𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬’ 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧

Tesla Mechanical Designs embeds safety into every aspect of machine design:

• Safety-First Philosophy: Safety features such as emergency stops, interlocks, guards, and barriers are integrated from the earliest design stages.

• Compliance with Global Standards: Designs adhere to international safety standards, including ISO, ASME, OSHA, and local codes, ensuring machines are market-ready and legally compliant.

• Risk Assessment and Mitigation: Comprehensive risk assessments are conducted during the design phase to proactively identify and eliminate hazards.

• Continuous Improvement: Feedback from field performance and regulatory updates is used to refine safety features in future designs.

Tesla Mechanical Designs’ unwavering commitment to safety protects users and clients alike, fostering trust and long-term success.

𝟓. 𝐑𝐢𝐠𝐨𝐫𝐨𝐮𝐬 𝐏𝐫𝐨𝐭𝐨𝐭𝐲𝐩𝐢𝐧𝐠 & 𝐓𝐞𝐬𝐭𝐢𝐧𝐠: 𝐕𝐚𝐥𝐢𝐝𝐚𝐭𝐢𝐧𝐠 𝐟𝐨𝐫 𝐎𝐩𝐭𝐢𝐦𝐚𝐥 𝐏𝐞𝐫𝐟𝐨𝐫𝐦𝐚𝐧𝐜𝐞

The Problem: Inadequate Testing and Validation

Skipping or rushing the testing phase can allow critical flaws to go undetected until after deployment, leading to costly recalls or failures.

𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬’ 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧

Tesla Mechanical Designs’ validation process is comprehensive and meticulous:

• Iterative Prototyping: Designs are refined through multiple iterations, with each prototype subjected to increasingly rigorous tests.

• Simulation and Analysis: Advanced tools like FEA and CFD are used to simulate performance under a range of conditions, identifying weaknesses before physical prototypes are built.

• Real-World Testing: Physical prototypes are tested in operational environments to validate performance, durability, and safety.

• Certification Support: The team assists clients in securing necessary certifications, ensuring a smooth path to market without regulatory hurdles.

This disciplined approach to prototyping and testing ensures that every machine design is validated for optimal performance and reliability before full-scale production.

𝐏𝐚𝐫𝐭𝐧𝐞𝐫𝐢𝐧𝐠 𝐟𝐨𝐫 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐄𝐱𝐜𝐞𝐥𝐥𝐞𝐧𝐜𝐞

Tesla Mechanical Designs’ machine design services is defined by its ability to help clients avoid the five most critical mistakes in the industry. By engineering for real-world conditions, prioritizing maintainability, selecting the right materials, ensuring uncompromised safety, and validating every design through rigorous testing, Tesla Mechanical Designs sets new standards for custom manufacturing solutions excellence.

Clients who partner with Tesla Mechanical Designs gain more than just a vendor—they gain a trusted engineering ally committed to delivering machines that are robust, efficient, and future-ready. With a global reach and a relentless focus on innovation, Tesla Mechanical Designs is the smart choice for organizations seeking to outpace the competition and achieve lasting success in the world of machine design.

For more information or to schedule a consultation, contact Tesla Mechanical Designs - https://www.teslamechanicaldesigns.com/contact-us.php or Visit our official website - https://www.teslamechanicaldesigns.com

Divya Dave

Tesla Mechanical Designs

+1 214-699-6163

email us here

Visit us on social media:

LinkedIn

Bluesky

Instagram

Facebook

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.